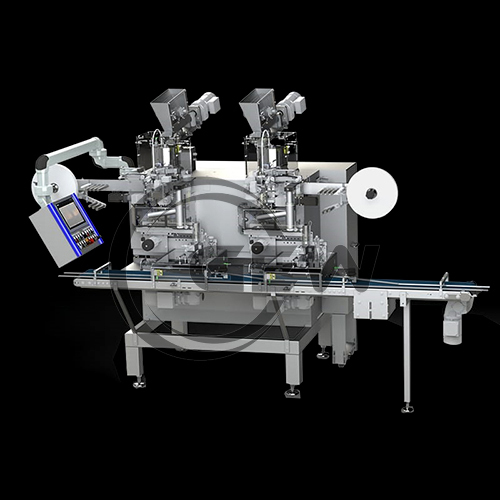

Water pouch packing machine

Price 150000.0 INR/ Piece

MOQ : 1 Piece

Water pouch packing machine Specification

- Application

- AUTOMATIC

- Filling Range

- 40 POUCH PER MIN

- Usage

- INDUSTRIAL

- Type

- Filling Machine

- Material

- STAINLESS STEEL

- Feature

- Durable, Highly Efficient, Heavy Duty Machine

- Capacity

- 2400 Pcs/hr

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- Human Machine Interface

- Drive Type

- Electric

- Weight (kg)

- 100 Kilograms (kg)

- Color

- Silver

- Warranty

- 2 YEARS

- Sealing Type

- Heat Sealing

Water pouch packing machine Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- faridabad

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 5 Pieces Per Week

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- standard

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- tradeindia

About Water pouch packing machine

A water pouch packing machine is a type of automatic packaging equipment designed specifically to fill and seal water in pre-formed pouches or bags. These machines are widely used in the beverage industry, especially for low-cost packaging of drinking water in sachets or small pouches, often in developing countries. Here's a detailed description:

Water Pouch Packing Machine Description

Function:

Automatically forms pouches from roll stock (or uses pre-formed pouches), fills them with purified water, and seals them for distribution.

Main Features:

Automatic Operation: Includes film unwinding, pouch forming, filling, sealing, and cutting in one continuous process.

Filling System: Uses gravity flow, piston, or volumetric pumps for accurate water filling.

Sealing System: Heat sealing (vertical and horizontal) ensures leak-proof pouches.

Material Compatibility: Works with laminated films such as PET/PE, NY/PE, or LDPE rolls.

Output Capacity: Typically ranges from 10003000 pouches per hour, depending on the model.

Pouch Size: Adjustable; common sizes are 200 ml, 250 ml, or 500 ml.

Key Components:

Film Roll Mount & Unwinder

UV Sterilization Unit (optional for hygienic applications)

Date Coding System

PLC Controller or Touchscreen Interface

Temperature Controllers for sealing accuracy

Stainless Steel Contact Parts (usually SS304 or SS316 for food-grade safety)

Common Applications:

Drinking water sachets

Flavored water or electrolyte drinks (in some models)

Small-scale beverage packaging

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Packaging Machine Category

tea bag packging machine

Price 750000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Silver

Warranty : 2 year

10 Head Automatic Weight Filler Packaging Machine

Price 1400000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : Heavy Duty Machine, Durable

Color : Silver

Warranty : 1 Year

Application : Packaging

Two Head Filler Khaini Packaging Machine

Minimum Order Quantity : 1 Unit

Feature : Heavy Duty Machine, Durable

Color : Silver

Warranty : 1 Year

Application : Packaging

FFS PNEUMATIC LIQUID POUCH PACKING MACHINE

Price 240000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : Heavy Duty Machine, Durable

Color : Silver

Warranty : 1 Year

Application : Packaging

Global Engg Works

GST : 06DLUPS8867M1ZN

GST : 06DLUPS8867M1ZN

Gali No-04, Plot No- 05, Railway Road, Kharkhana Bagh, Mathura Road, Old Faridabad,Faridabad - 121002, Haryana, India

Phone :07971258559

|

Global Engg Works

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry