PNEUMATIC AUTOMATIC AUGER FILLER MACHINE

Price 350000.0 INR/ Unit

MOQ : 1 Piece

PNEUMATIC AUTOMATIC AUGER FILLER MACHINE Specification

- Application

- Packaging

- Filling Range

- 25PCS MINUTE

- Features

- AUTOMATIC

- Usage

- Industrial

- Type

- Filling Machine

- Material

- Stainless Steel

- Feature

- Heavy Duty Machine, Durable

- Capacity

- 1300 Pcs/hr

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- Human Machine Interface

- Drive Type

- Electric

- Color

- Silver

- Warranty

- 2 Year

PNEUMATIC AUTOMATIC AUGER FILLER MACHINE Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- FARIDABAD

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- STANDARD

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- TRADEINDIA

About PNEUMATIC AUTOMATIC AUGER FILLER MACHINE

A Pneumatic Automatic Auger Filler Machine is a high-precision, semi- to fully-automatic filling system designed for dispensing powdered and granular materials into containers such as bottles, jars, pouches, or cans. It utilizes an auger screw driven by a motor and controlled by a pneumatic system to ensure accurate, consistent dosing.

This type of filler is ideal for products such as spices, flour, coffee powder, protein supplements, chemical powders, talc, and similar non-free-flowing materials.

Key Features:

Pneumatic Control System: Enhances operational stability and precision during the filling process.

Auger Screw Mechanism: Provides accurate filling by volume or weight, depending on configuration.

Touchscreen Interface (HMI): Enables easy setup of filling parameters and recipe storage.

Servo or Stepper Motor Options: For high accuracy and repeatability.

Stainless Steel Construction: Ensures hygiene, durability, and compliance with food and pharma standards.

Automatic Bottle/Pouch Detection: Prevents product waste by filling only when a container is present.

Dust Control Mechanisms: Helps maintain a clean working environment.

Applications:

Food industry (milk powder, spices, flour)

Pharmaceuticals (talcum, medicinal powders)

Chemicals (detergent powders, additives)

Cosmetics (face powder, bath salts)

Advantages:

Consistent and precise filling

Reduced operator fatigue and labor

High-speed production with minimal downtime

Easy to clean and maintain

Customizable for a wide range of container sizes and shapes

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Packaging Machine Category

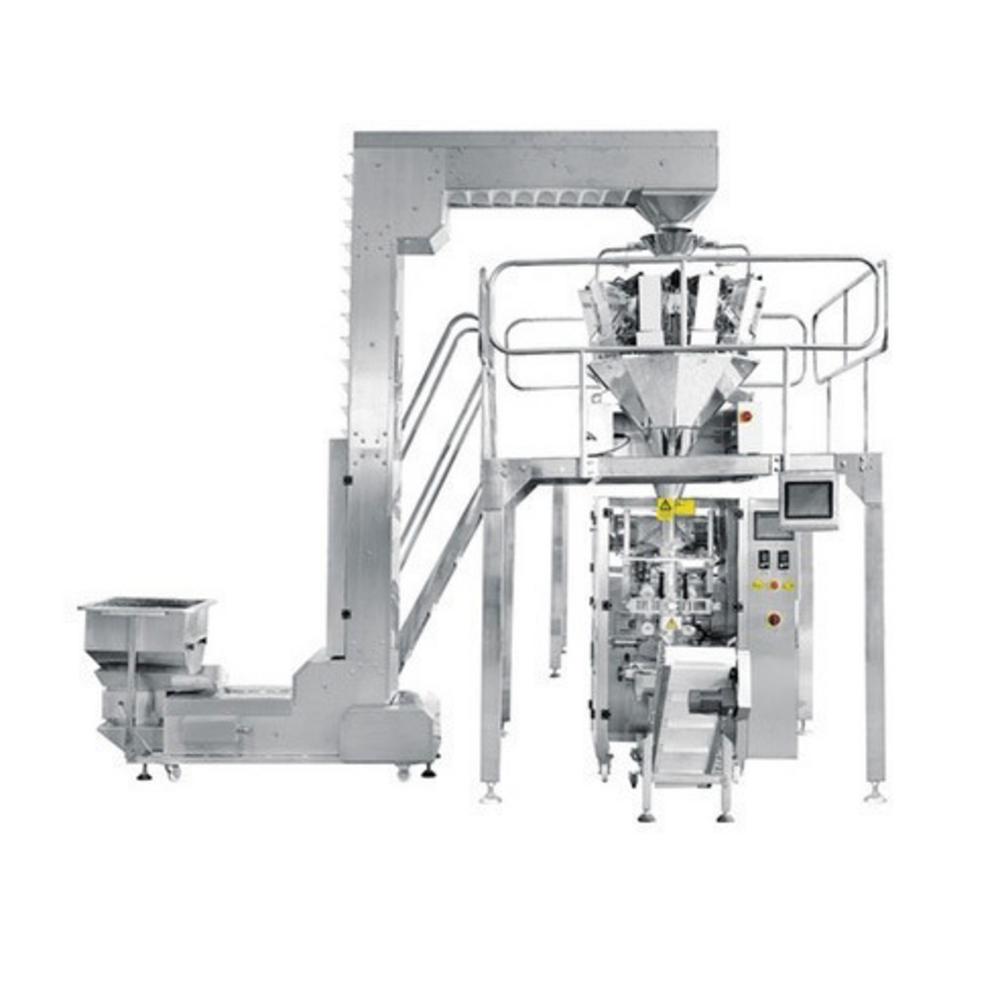

Fully Multi-head Weigher Machine

Price 1250000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Packaging

Warranty : 2 Year

Color : Silver

Automatic Grade : Automatic

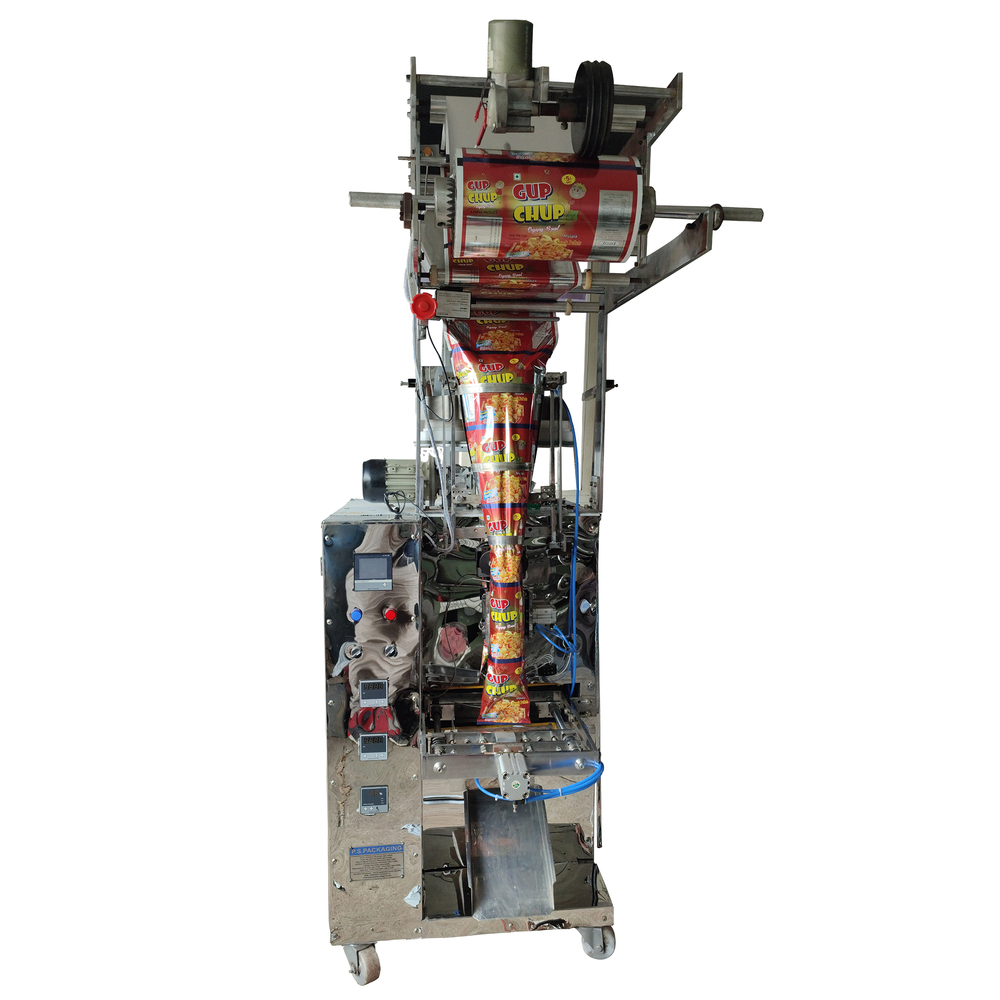

pneumtic cup filler khaini pouch packging machine

Price 750000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Packaging

Warranty : 1 Year

Color : Silver

Automatic Grade : Automatic

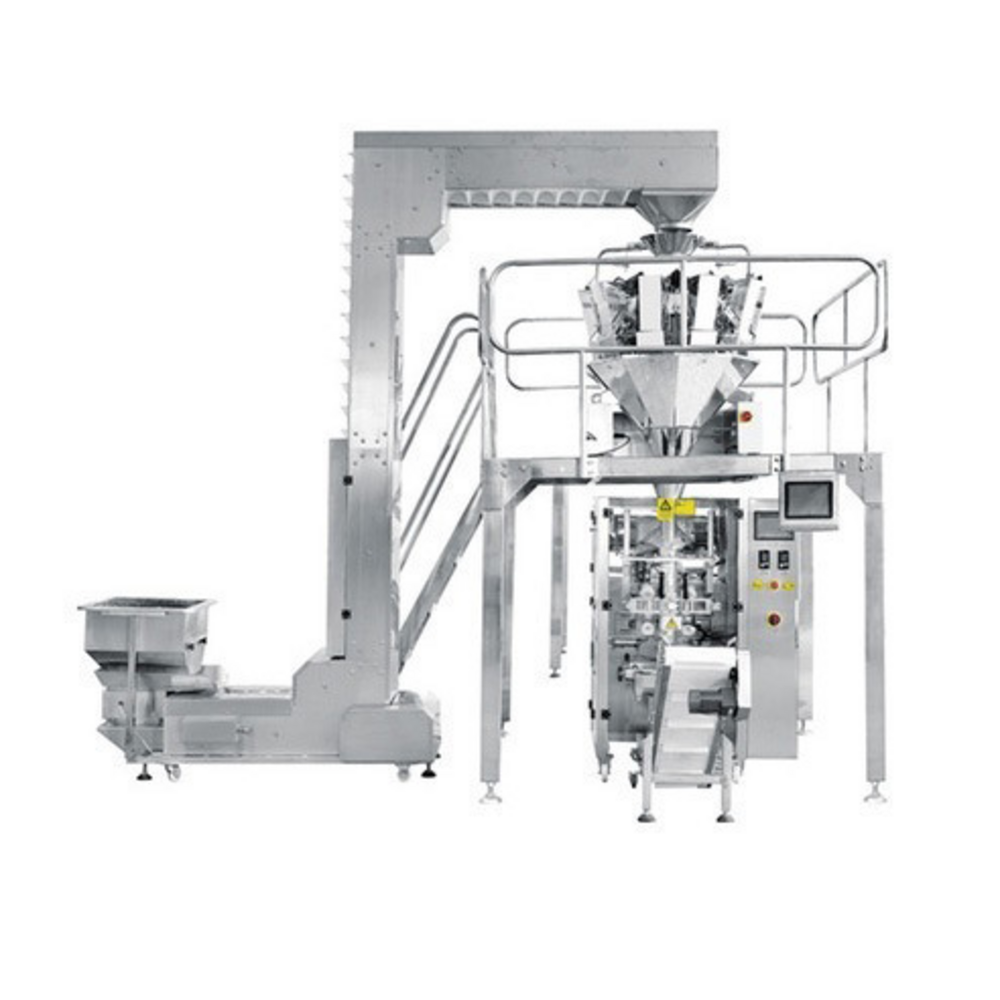

Fully Automatic Auger Filler Powder Packaging Machine

Price 350000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Packaging

Warranty : 1 Year

Color : Silver

Automatic Grade : Automatic

Multitrack Automatic Packaging Machine

Price 1550000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Packaging

Warranty : 1 Year

Color : Silver

Automatic Grade : Automatic

Global Engg Works

GST : 06DLUPS8867M1ZN

GST : 06DLUPS8867M1ZN

Gali No-04, Plot No- 05, Railway Road, Kharkhana Bagh, Mathura Road, Old Faridabad,Faridabad - 121002, Haryana, India

Phone :07971258559

|

Global Engg Works

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry